The P&G Blog

2/25/2026

Scaling Solutions Across Industries That Reduce Environmental Impact

Discover how P&G’s partnerships and innovations help scale sustainability solutions across industries, advancing circularity and collective impact.

Read more

2/25/2026

Unraveling the Hair Loss Challenge: Introducing Pantene Abundant & Strong

Pantene’s Abundant & Strong Collection offers a science-backed solution for hair loss, increasing density and empowering women to regain their confidence.

Read more

2/25/2026

P&G's Awards and Recognitions: Shaping Careers, Inclusion and Consumer Impact

Unveiling Procter & Gamble's prestigious honors and commitment to excellence in all aspects.

Read more

2/19/2026

P&G at the 2026 Consumer Analyst Group of New York (CAGNY) Conference

Leaders spoke with a group of investors about P&G's integrated growth strategy.

Read more

2/16/2026

P&G's Education Partnerships Support Communities and Shape Tomorrow's Leaders

Discover how P&G's education partnerships shape tomorrow’s leaders and support community and business growth.

Read more

2/10/2026

P&G and Brandi Carlile’s Looking Out Foundation: Supporting the LGBTQ+ Community in Partnership

Advancing equality and inclusion through a long-term partnership providing sustained support for LGBTQ+ organizations around the world

Read more

2/10/2026

From Lab to Launch: P&G's "Out of This World Ideas” Innovation Challenge Inspires Young Women in STEM

Discover how P&G is inspiring the next generation of women scientists and innovators.

Read more

2/10/2026

P&G Brands to Serve Olympic and Paralympic Winter Games Athletes

P&G offers top-performing household personal care products and services at Olympic and Paralympic Winter Games Milano Cortina 2026

Read more

2/9/2026

Where Curiosity Meets Purpose: How Inventors Thrive at P&G

Meet three inventors shaping the future of P&G.

Read more

2/6/2026

Multi-Generational Families at P&G: The Legacy Continues

Meet the Lea Family: Fostering a sense of belonging through family bonds and mutual mentorship.

Read more

1/26/2026

Accelerating Innovation: Wonderbelly Joins the P&G Personal Health Care Portfolio

Expanding P&G’s commitment to personal health by delivering effective, 'free-from' digestive relief to a wider range of shoppers

Read more

1/26/2026

P&G's Ultimate Denim Care Guide: How to Wash, Wear and Preserve Your Favorite Jeans

Jean-ius guidance from P&G Fabric Care to extend the life of your favorite pair.

Read more

1/26/2026

Celebrating Excellence: Honoring P&G’s Top-Performing External Business Partners

Company recognizes 40 top-performing suppliers committed to performance, partnership and excellence.

Read more

1/22/2026

P&G Announces Results for the Second Quarter of Fiscal Year 2026

P&G reported results for the second quarter of fiscal 2026.

Read more

1/15/2026

Beyond the Podium: Olympians and Paralympians Turning Passion Into Purpose with Grants Fueling Their Community Impact

Athletes for Good program provides $26,000 grants to charities championed by 10 Olympic and Paralympic Winter Games athletes

Read more

1/8/2026

Concept to Counter: P&G Drives Skincare Innovation with OLAY Cleansing Melts

Our integrated R&D, IT, and Product Supply collaboration transformed a decade of patented water-free science into a market-ready, sustainable skincare solution.

Read more

1/8/2026

P&G Ventures: Building the Future

Creating new categories through bold, consumer-first innovation.

Read more

1/7/2026

Growing Potential: How P&G’s Commitment to Mentorship Supports Partners and Communities

Discover how P&G's partnerships and mentorship initiatives cultivate talent, serve consumers, and strengthen communities for shared success.

Read more

12/19/2025

Australia & Southeast Asia: Listening to Women Inspired Pantene’s Next Haircare Miracle

How Pantene Turned 3 Minute Miracle into a Full Regimen

Read more

12/19/2025

Unlocking Peak Performance: How P&G Prioritizes Total Employee Wellbeing

How P&G supports the physical, mental, financial and work-life wellbeing of employees throughout their career journeys.

Read more

12/4/2025

Native American Heritage Month: Flowing Together with Water Restoration Projects

P&G is helping build a Water Positive Future in partnership with Native American communities with deep knowledge of local water challenges and solutions.

Read more

12/2/2025

A World of Abilities: P&G's Journey Toward Disability Confidence

Discover How P&G and Its Brands Celebrate and Support Disability Confidence on International Day of People with Disabilities and Everyday

Read more

11/25/2025

Always Pocket Flexfoam Redefines On-the-Go Period Protection

Flexfoam’s superior design, performance and experience come together to deliver superior period protection for your busy lifestyle.

Read more

11/17/2025

Pampers Introduces the World’s Tiniest Diaper for the Tiniest Fighters

The Pampers Swaddlers Pxxs diaper builds on the brand’s trusted legacy of innovation and support for babies and families.

Read more

11/13/2025

Beyond the Bottle: How Gemz is Redefining Haircare for the Modern Consumer

After 14 years of R&D, P&G introduces Gemz, a first-of-its-kind, water-activated haircare solution.

Read more

10/31/2025

How to Stand Out: Tips for Shining in the P&G Application Process

At P&G, the hiring process focuses on understanding candidates, their work approach and their potential long-term fit, rather than just keywords or right answers.

Read more

10/24/2025

P&G Announces Results for the First Quarter of Fiscal Year 2026

P&G reported results for the first quarter of fiscal 2026.

Read more

10/24/2025

As You Care for Others, We're Here for You: P&G and Care Out Loud Support Caregivers

P&G and Care Out Loud team up to support caregivers. Get resources, a special CVS offer, and learn how P&G cares for those who care.

Read more

10/17/2025

P&G Innovates for Every Stage of Life

Explore how P&G supports women through every stage of life, including menopause, with employee resources and superior brand solutions designed for their unique needs.

Read more

10/14/2025

Working Towards More Sustainable Packaging Solutions

Learn more about how our progress is driven by innovative, sustainable packaging solutions and expanding change through investments and partnerships.

Read more

10/13/2025

Money Matters: P&G Empowers Employees to Improve Their Financial Wellbeing

Employees share how the educational resources P&G provides empowered them to gain confidence on their financial wellbeing journeys and help them reach meaningful goals.

Read more

10/7/2025

Mentorship Reversed: P&G's Strategy for a More Agile, Digitally Fluent Future

Mentorship has long been part of the P&G learning culture but now, some of the most transformative mentoring relationships are happening in reverse.

Read more

10/6/2025

P&G Ventures: Where Brands Are Born

Creating new brands in new spaces to help consumers live life better.

Read more

10/6/2025

Zevo

The future of pest control.

Read more

10/6/2025

Spruce

The future of weed control.

Read more

10/2/2025

The Power of Clean Water: P&G Children’s Safe Drinking Water Program Reaches 25 Billion Liters

Learn how the P&G Children’s Safe Drinking Water Program, together with 150+ partners, has delivered 25 billion liters of clean water around the world.

Read more

10/1/2025

Expanding Support of Water Restoration Initiatives Around the World

Water restoration initiatives underway in China and India.

Read more

9/26/2025

P&G and WWF: 15 Years of Partnership for a Sustainable Future

We are proud to celebrate a remarkable milestone: 15 years of partnership between Procter & Gamble and World Wildlife Fund.

Read more

9/19/2025

The Power of Partnership: P&G’s Spruce and The Ohio State University

P&G and Ohio State University joined forces, making a significant impact on Lawn & Garden care with the development of Spruce.

Read more

9/17/2025

How P&G Supports Deaf and Hard-of-Hearing Communities to Build a #DisabilityConfident Culture for All

Discover how P&G supports our D/deaf and hard-of-hearing communities.

Read more

9/17/2025

The Benefit of Time: How P&G Employees Use Sabbaticals to Support Wellbeing

Colleagues share how time away helped them re-evaluate, refresh and reground.

Read more

9/10/2025

P&G Innovations Are Elevating Everyday Experiences

How we’re meeting modern demands by providing innovative solutions tailored for today’s consumers.

Read more

9/5/2025

Back on the Yard: P&G Brands and HBCYOU Program Help Students Game Plan for Campus Life

Learn how P&G’s HBCYOU Program supports student success with essential brand products.

Read more

9/2/2025

The Plant Perspective: Celebrating People, Excellence & Innovation

Discover how Product Supply drives growth, delivers value and maintains P&G's competitive advantage.

Read more

8/30/2025

P&G Releases 2025 Annual Report

P&G’s 2025 Annual Report highlights P&G’s integrated growth strategy.

Read more

8/23/2025

World Water Week: Contributing to a Water Positive Future

Our comprehensive strategy is focused on reducing water in our operations.

Read more

8/15/2025

Mentorship Fuels Growth, Belonging and Longevity at P&G

At P&G, mentors are more than helpful resources — they are powerful forces behind a thriving, inclusive culture that grows talent from within.

Read more

8/8/2025

Learn More About P&G’s Climate Initiatives and Net Zero Ambition

Climate change action and waste reduction align with P&G's ambition of net zero greenhouse gas emissions by 2040.

Read more

8/8/2025

Helping to Protect Critical Ecosystems: Learn About P&G’s Ambition for Nature

Learn how P&G is supporting the natural ecosystems that support our business and beyond.

Read more

8/8/2025

Waste Reduction, Plastics and Recycling: Learn About P&G’s Actions

Discover how P&G is embedding sustainable practices into our operations and products.

Read more

8/8/2025

Helping Create a Water Positive Future: Learn More About P&G’s Strategy

Discover the elements of P&G’s water positive future strategy.

Read more

7/30/2025

P&G Announces Results for the Fourth Quarter and Fiscal Year 2025

P&G reported results for the fourth quarter and fiscal year 2025.

Read more

7/25/2025

Together, We’re IN: Building #DisabilityConfidence at the 2025 Disability:IN Conference

Learn about P&G’s time at the 2025 Disability:IN Conference.

Read more

7/19/2025

Showing Up When It Matters Most: 12 Months of P&G Disaster Relief Impact

Learn how P&G, our partners and our brands deliver essential products and services to communities recovering from disasters.

Read more

7/3/2025

P&G’s InQbet: Driving Innovation Through Start-Up Collaborations

P&G’s European accelerator hub is fueling “constructive disruption” sustainable innovation.

Read more

7/2/2025

Dash Turns 60!

Dash celebrates 60 years in Italy, marking a journey that began in 1965 and revolutionized the way people do laundry.

Read more

6/28/2025

Reimagining Everyday Products: P&G Brands Dominate Circana's 2024 Pacesetters Report

P&G brands lead the way in Circana's 2024 Pacesetters Report, securing top ranks and demonstrating innovation in products that address consumer needs.

Read more

6/28/2025

From Internship to Impact: How P&G Interns Make a Difference from Day 1

Meaningful work, leadership development and innovative thinking are keys to helping P&G interns succeed.

Read more

6/26/2025

Timeless Creativity at Cannes Lions 2025: How P&G Is Building Brands That Last

P&G brand builders and valued partners from around the world gathered for conversations around timeless creativity that builds lasting brands.

Read more

6/12/2025

Flowing with Purpose: Supporting New Water Restoration Initiatives in Mexico

P&G’s progress toward water restoration ambitions with support of new water restoration initiatives in Mexico.

Read more

6/5/2025

Fueling Growth and Value Creation through Productivity

Highlights from 2025 Deutsche Bank Global Consumer Conference.

Read more

6/5/2025

Innovation at Scale: How P&G Transforms Business Through Technology

P&G is incorporating emerging technologies in all areas of the business to better serve consumers, upskill our employees and drive business growth.

Read more

5/30/2025

Celebrating AAPI Voices:

How P&G Supports Partners Working to Tell the Stories of Our Communities

Discover how P&G connects with consumers through partners like TAAF and Gold House that amplify AAPI voices, enable authentic storytelling and support communities.

Read more

5/30/2025

P&G Brands and Partners: Building Healthier Communities, Together

Discover how P&G brands like Pampers and Tampax are partnering with organizations like BWHI and YMCA to build healthier communities.

Read more

5/26/2025

P&G’s North America Logistics Summit Honors Top Carriers and Suppliers

Nearly 250 attendees from transportation and carrier partners convened to recognize P&G’s carrier community.

Read more

5/9/2025

TIME101, in Partnership with P&G, Honors Matthew 25: Ministries

Learn how P&G partners with TIME101 honoree Matthew 25: Ministries to deliver relief to communities impacted by natural disasters.

Read more

5/3/2025

Here’s How We Keep Sustainability Front and Center for Our People

P&G’s Chief Sustainability Officer, Virginie Helias, reflects on how we demonstrate sustainability is a foundational part of our business strategy.

Read more

5/3/2025

How Can Partnerships Move Us toward a Circular Future Faster?

Advancing a circular future: P&G’s collaborations towards sustainable packaging solutions.

Read more

4/30/2025

Weeding Without Worry: Meeting Unmet Consumer Needs Outside with Spruce

Introducing Spruce: the new hardworking and worry-free weed & grass killer.

Read more

4/30/2025

Speak Up, Reach Out: How P&G is Empowering Employees to Advocate for Their Wellbeing

Four employees share how P&G offers a holistic approach to wellbeing that meets them where they are and supports them throughout all of life’s stages.

Read more

4/26/2025

P&G's Women in Water: Building a Water Positive Future, Together

Meet some of the women at P&G leading the charge for a sustainable future, and discover how our culture of inclusion is driving innovation and impact.

Read more

4/25/2025

P&G Announces Results for the Third Quarter of Fiscal Year 2025

P&G reported results for the third quarter of fiscal 2025.

Read more

4/18/2025

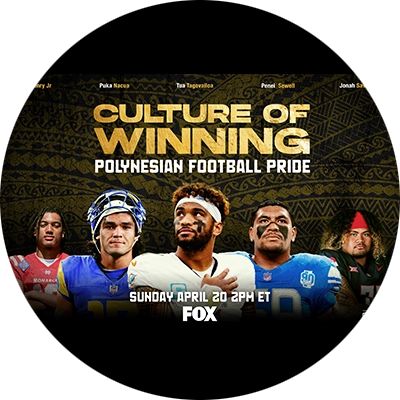

P&G's "Culture of Winning": Celebrating Community and Inclusive Storytelling

Learn about P&G Studios’ new film, “Culture of Winning,” and how P&G’s inclusive storytelling connects its brands to consumers.

Read more

4/17/2025

Exploring Dissolution Recycling with P&G Packaging Expert Gian De Belder

Gian De Belder discuses how P&G’s new dissolution recycling technology transforms hard-to-recycle plastics, enhancing sustainability and reducing carbon footprints in the packaging industry.

Read more

4/15/2025

P&G Brands Recognized for Packaging That’s Accessible and Sustainable

Learn about our brands’ inclusive products and packaging that also help consumers live more sustainably.

Read more

4/10/2025

Febreze Unveils Vanilla Suede as 2025 Scent of the Year

Elevate your home with the scent of comfort and indulgence: Febreze Selects Vanilla Suede as the 2025 Scent of the Year.

Read more

4/5/2025

What’s the Key to a Winning Sustainability Strategy? Integration.

Learn how P&G embeds sustainability into our company’s business strategy.

Read more

4/4/2025

The Future of Collaboration: How AI is Supplementing Teamwork and Innovation at P&G

A P&G study with academic partners demonstrates the benefits of AI across the organization.

Read more

4/3/2025

Dawn PowerSuds is Revolutionizing Your Cleanup Routine

Learn about P&G’s latest innovation Dawn PowerSuds, the innovators behind it and how together they’re revolutionizing cleaning.

Read more

3/25/2025

Responding to Water Challenges Through Innovation and Partnerships

The 50L Home — showing how we can save water and energy at home while improving consumer delight.

Read more

3/21/2025

Monica Turner Shares 3 Tips for Building an Innovative Culture

At the 2024 EY Strategic Forum, P&G North America President Monica Turner shared how P&G is creating an innovative and entrepreneurial culture by attracting and developing talent.

Read more

3/18/2025

Global Recycling Day 2025: Celebrating Award-Winning Sustainable Packaging Innovations

This Global Recycling Day 2025, discover award-winning sustainable packaging innovations that redefine convenience and accessibility.

Read more

3/11/2025

How P&G Brands Serve Women and Girls: Then. Now. Next.

From Lenox Soap to leading in the lab, learn how P&G brands have served women and girls throughout the years and every day.

Read more

2/27/2025

Clean Water, Transformed Lives: The P&G Children's Safe Drinking Water Program

Learn how P&G Children’s Safe Drinking Water Program has innovated and partnered to deliver life-changing clean water around the world.

Read more

2/27/2025

Welcome In: P&G’s Groundbreaking New Soap Opera Beyond the Gates Premieres This February

Learn how P&G invented the soap opera and its new show Beyond the Gates.

Read more

2/22/2025

OLAY Launches Super Serum Body Wash

The brand’s most advanced body wash delivers powerful results typically associated with high-end facial products.

Read more

2/20/2025

Supplying Your Favorite Products: From Production to Your Home

A sneak peek inside the journey your favorite products take to arrive at their destination.

Read more

2/13/2025

The Art and Science of Improving Everyday Household Products

Learn how P&G's consumer-driven approach transforms household products and makes jobs-to-done easier and more efficient.

Read more

2/6/2025

Transform Your Home with the New Febreze PLUG Scent Booster

Learn the secret to a perfectly scented home with the Febreze PLUG Scent Booster and transform your home into a fragrance haven.

Read more

1/23/2025

P&G Announces Results for the Second Quarter of Fiscal Year 2025

P&G reported results for the second quarter of fiscal 2025.

Read more

1/14/2025

How Inspirational Leaders Ignite Our Purpose: P&G's Culture of Inclusion Fuels Our People and Innovation

How four inspirational leaders help build a culture of inclusion to serve our employees, consumers and communities.

Read more

1/11/2025

Meet the 2024 P&G Signal Innovators

Learn how P&G innovators from the Signal 2024 Summit are leveraging AI to enhance consumer insights and drive product innovation.

Read more

12/20/2024

Top 3 Lessons from P&G Employees in 2024

Employees reflect on a year of building confidence, trust and leadership.

Read more

12/19/2024

Transform Cleaning with P&G's Superior Home Care Innovations: Faster, Easier, Better

Discover how P&G’s offerings deliver a superior clean and give you more time.

Read more

12/17/2024

Celebrating the Leaders of Brand Success: The 2024 P&G Best of Brand Awards and Brand Mastery Society Induction

Learn about P&G’s commitment to brand building and the 2024 Best of Brand Award winners.

Read more

12/13/2024

Celebrating the 100th Anniversary of P&G Analytics & Insights:

Learn about P&G’s century of impact, the principles of our approach and hopes for the future of the analytics and insights industry.

Read more

12/13/2024

Winning at Shelf: How P&G Delivers Superior Retail Execution

Learn how P&G makes shopping easier with superior retail execution. Mindy Sherwood, Chief Sales Officer, shares her insights.

Read more

12/10/2024

The Science Behind Superior Products: From Insight to Innovation

How deep understanding, combined brand expertise and advanced technology tools fuel products.

Read more

11/26/2024

Inside P&G’s Integrated Growth Strategy

Discover P&G’s five key choices to better serve people worldwide.

Read more

11/21/2024

3 Keys to Successful Digital Transformation

How P&G is advancing digital capabilities to address challenges consumers and retailers face in key areas like supply chain, retail execution and consumer communication.

Read more

10/26/2024

P&G Myth-Busting Series | Scientist Puts Charmin Smooth Tear to the Test

Explore the science behind Charmin Smooth Tear as P&G's Gregg Weaver debunks myths and showcases its superior design against traditional toilet paper.

Read more

10/19/2024

P&G Announces Results for the First Quarter of Fiscal Year 2025

P&G reported results for the first quarter of fiscal 2025.

Read more

9/14/2024

P&G Celebrates Hispanic Heritage Month 2024

Learn how Procter & Gamble is Honoring Hispanic Contributions and Unleashing Potential for Hispanic Youth.

Read more

9/13/2024

Beyond the Gold — Meet the Paralympians Making History in the New Rising Phoenix: What Does It Take? Podcast Series Supported by P&G

Discover P&G’s new podcast introducing the 2024 Paralympians making history.

Read more

8/24/2024

P&G Releases 2024 Annual Report

P&G's 2024 Annual Report highlights how P&G’s highly committed, creative and determined people remain focused on understanding and serving consumers.

Read more

8/20/2024

P&G European Innovators Behind the Innovation: Meet the Scientist Behind Babycare Europe

Meet Trang Le, R&D Product Research Scientist Babycare Europe

Read more

8/14/2024

Unveiling Secret Science: How Pampers Premium Protection Keeps Your Baby Comfortable

Go behind the scenes to explore the innovation behind Pampers Premium Protection diapers.

Read more

8/10/2024

Extraordinary Moments: Four P&G Colleagues Share Their Stories

Meet Archie, Ashley, Louie and Erika, who share their moving stories and how P&G supported them when they needed it most.

Read more

8/8/2024

Alex Keith on Balancing Tradition with Transformation in the Global Beauty Market

P&G Beauty’s Chief Executive Officer Alex Keith sat down with Shop Talk Europe’s Content Vice President Rebecca Bemhenna.

Read more

8/8/2024

P&G + Me = Mutual Success: Delivering a Superior Employee Value Equation

Employees have a lot of choices, and we know there is always more work to do to attract, develop and retain the best talent.

Read more

7/31/2024

P&G Announces Results for the Fourth Quarter and Fiscal Year 2024

P&G reported results for the fourth quarter and Fiscal Year 2024.

Read more

7/26/2024

P&G’s Signal Summit Put Market Growth & Value Creation in Focus

Industry leaders shared invaluable insights to inspire growth through creativity and constructive disruption.

Read more

7/12/2024

Three Ways P&G Grows Disability Confidence

Discover How P&G Supports Disability Confidence During Disability Pride Month and Everyday

Read more

6/28/2024

2024 Cannes Lions: Finding Creativity in the Everyday

P&G joined the 71st Cannes Lions International Festival of Creativity to discuss the future of creativity in advertising.

Read more

6/27/2024

The Power of P&G's History: Inspiring Innovation for Today and Tomorrow

From the original Swiffer prototype to groundbreaking insights, P&G's history fuels their commitment to improving lives every day.

Read more

6/14/2024

P&G Myth-Busting Series: Debunking Laundry Day Hacks

One of our P&G Laundry Experts shares tips to help level up your laundry game.

Read more

6/6/2024

P&G at the 2024 Deutsche Bank Global Consumer Conference

P&G Chief Operating Officer Shailesh Jejurikar and Chief Financial Officer Andre Schulten spoke with investors and analysts at the Deutsche Bank Global Consumer Conference.

Read more

6/6/2024

Signal 2024 | P&G’s Annual Innovation Summit Will Bring Together Visionary Leaders in Cincinnati

Industry leaders will share insights and strategies for driving market growth and value creation in today’s unpredictable global business environment.

Read more

6/5/2024

The Secret Behind P&G Innovation? Unleashing the Power of People

P&G’s unique employee experience helps individuals thrive and business grow.

Read more

6/4/2024

Reflecting on P&G’s Longstanding Commitment to Advancing LGBTQ+ Equality and Efforts to Better Serve the LGBTQ+ Community

This Pride Month, we’re recognizing the continued progress P&G has made to support the LGBTQ+ community through our brands, employees and partners.

Read more

5/22/2024

Innovation Series: Meet the plant manager running the largest family care site in the world

Innovators Behind the Innovation Series Continues with plant manager Cecilia Colburn

Read more

5/17/2024

Embracing Digital Accessibility: Empowering Everyone

Celebrating Global Accessibility Awareness Day at P&G: Our commitment to digital inclusivity for a more accessible digital world.

Read more

5/16/2024

Forging a Strategic Partnership with GLAAD to Help Ensure Accurate and Inclusive LGBTQ+ Representation

Brent Miller, Senior Director for Global LGBTQ+ Engagement, reflects on P&G’s longstanding partnership with GLAAD to further LGBTQ+ visibility in the media

Read more

5/9/2024

P&G Celebrates AAPI Heritage Month

Sustained actions continue to drive inclusion and impact for the AAPI community, from authentic storytelling to partnering with The Asian American Foundation.

Read more

4/27/2024

2024 It’s Our Home Sustainability Awards

Celebrating employees whose significant contributions are making a difference, accelerating progress, and creating value while reducing environmental impact.

Read more

4/27/2024

People, Brands and Partners Doing Acts of Good to Help Communities Grow

Discover how P&G and our brands — like Always, Crest, Pampers and Tide — are making a positive impact across communities.

Read more

4/27/2024

Key P&G Suppliers Honored with 2024 Partner of the Year Awards

P&G Partner of the Year Awards: celebrating suppliers' exceptional contributions and business value.

Read more

4/25/2024

Unlocking Solutions to Water Challenges in New “Our Blue World, A Water Odyssey” Documentary

Discover how P&G's partnerships and innovative solutions help address the global water crisis in the documentary "Our Blue World: A Water Odyssey."

Read more

4/24/2024

Introducing Tide evo: A Leap Forward in Laundry

A decade of innovation culminates in revolutionary new laundry tile debuted at SXSW 2024.

Read more

4/23/2024

Made Better, Made to Save

New P&G survey reveals how everyday tasks add a physical and mental load to people’s already hectic days.

Read more

4/20/2024

P&G Announces Results for the Third Quarter of Fiscal Year 2024

P&G reported results for the third quarter of Fiscal Year 2024.

Read more

4/11/2024

P&G Myth-Busters Series: Body Odor happens but you don’t have to smell

Meet one of the Innovators behind whole body deodorant: Dr. Maiysha Jones

Read more

4/4/2024

Dear Younger Self: 3 Lessons From a P&G Executive

Fama Francisco, P&G CEO of Global Baby, Feminine, and Family Care, shares personal learnings from her 35 years in the company.

Read more

4/3/2024

Shailesh Jejurikar Talks About Unlocking Market Growth

P&G’s Chief Operating Officer Shailesh Jejurikar sat down with Yahoo! Finance Executive Editor Brian Sozzi to discuss how companies can drive growth and unlock opportunities for all stakeholders.

Read more

3/30/2024

Personal Growth, Purpose and Making a Difference for Employees at P&G

P&G + Me = Mutual Success | 7 P&G Employees Share Their P&G Stories

Read more

3/22/2024

From Failure to Launch: How P&G’s Heritage Inspires Innovation

For more than 187 years, P&G has been improving lives with industry-leading products. Understanding our rich history is key to meeting consumer needs.

Read more

3/19/2024

4 P&G Brands Delivering on Superior Innovation

Learn more about how these latest innovations demonstrate P&G’s ongoing commitment to irresistible superiority.

Read more

3/16/2024

P&G Recognizes LGBTQ+ Cultural Moments in the UK and Australia During February

P&G Australia Supports Sydney Gay and Lesbian Mardi Gras, while P&G UK recognizes the importance of LGBTQ+ History Month.

Read more

2/23/2024

A Focus on Balanced Growth and Value Creation

Highlights from P&G’s Consumer Analyst Group of New York (CAGNY) Conference 2024.

Read more

2/10/2024

Black History Month: Meet the Innovators Behind P&G’s Everyday Innovations

Throughout Black History Month P&G is celebrating our innovators and the innovation behind the products they make and that help make the lives of our consumers better every day.

Read more

2/2/2024

P&G Honors Black History Month 2024

Discover the impact of Black creativity as P&G celebrates Black creatives, innovators, cultural institutions and media companies during Black History Month.

Read more

1/24/2024

P&G Announces Results for the Second Quarter of Fiscal Year 2024

P&G reported results for the second quarter of Fiscal Year 2024, with a strong quarter driven by the continued excellent execution of our integrated strategy.

Read more

1/13/2024

The Art of Leadership: Uncovering Three P&G Secrets to People Development

Find out what’s behind P&G’s long-standing reputation as an academy for future CEOs.

Read more

1/12/2024

Meet the P&G Innovator Doing Laundry in Space

P&G Innovator Mark Sivik works on Tide Infinity, helping astronauts do laundry in space.

Read more

1/5/2024

P&G Myth-Busting Series: The Science Behind Braun's New IPL Hair Removal System

Braun launches new IPL hair removal system that auto-adjusts to user during treatment.

Read more

1/4/2024

Meet the Innovator Behind Braun’s New IPL Hair Removal System

P&G Scientist: “Hair removal innovation makes getting ready easier.”

Read more

12/15/2023

P&G Receives Perfect Score on HRC Equality Index for 10th Consecutive Year

Recognizing P&G’s policies, practices and benefits that create an inclusive workforce.

Read more

12/14/2023

Diving Into Action: Supporting New Water Restoration Projects in California

We kicked off four water restoration projects with on-the-ground partners in California, as part of P&G’s water positive future strategy.

Read more

12/5/2023

Creating Workspaces that Work for Everyone

Take a sneak peek inside some of our offices to see how we’re making P&G workspaces around the globe more accessible and inclusive.

Read more

12/5/2023

Meet the European Summit Innovators

Learn more about our European scientists that are driving product innovation with sustainability in mind.

Read more

11/30/2023

Disability Confident: P&G’s Inclusive Workplace Grows Innovation, Careers and Business

Learn more about Procter & Gamble’s efforts to remove the barriers that inhibit access within society for people with disabilities, through inclusive representation and accessible design.

Read more

11/30/2023

Three Ways Widen The Screen Is Widening Our View As We Serve Black Consumers.

P&G Expands Widen The Screen’s Impact by Widening Our View of Black Life and Culture.

Read more

11/28/2023

P&G and World Resources Institute on the Importance of Setting Downstream Water Targets

P&G worked closely with the World Resources Institute Water Program to align with the best science and emerging target-setting practices.

Read more

11/21/2023

Febreze Draws on Unlikely Inspiration for New Innovation

P&G scientists created the AIRIA Smart Scent Diffuser with inspiration from thermal ink-jet printer cartridge technology.

Read more

11/17/2023

Building a Family: Celebrating the Beauty of Adoption

For National Adoption Day, learn how P&G supports employees during the parenthood journey.

Read more

11/16/2023

P&G Introduces Digital Watermarking Test in France for Enhanced Recycling

Through partnership and innovation, this is a step toward ensuring more waste is collected and recycled.

Read more

11/1/2023

Meet the 2023 P&G Signal Innovators

Meet the P&G innovators who were featured at the Signal 2023 Summit.

Read more

10/28/2023

For the First Time in 100 years, Charmin is Reinventing the Square for a Smoother Tear

P&G CEO Jon Moeller credits “a great team of innovators.”

Read more

10/25/2023

Pampers Innovates to Help Prevent One of Parents’ Worst Diaper Fears

Pampers’ newest innovation, the Blowout Barrier, keeps babies dry and puts parents’ fears to rest.

Read more

10/20/2023

Empowering Employee ‘P&G + Me’ Stories

Hear in their own words why these team members say P&G is the best place to build a career.

Read more

10/20/2023

P&G Innovates for Any Age and Every Stage of Life

Reflecting on World Menopause Day: how P&G helps deliver products that make consumers lives easier, no matter what stage of life they’re in.

Read more

10/19/2023

P&G Announces Results for the First Quarter of Fiscal Year 2024

P&G reported results for the first quarter of Fiscal Year 2024, and our integrated strategy continued to support strong results.

Read more

10/11/2023

P&G's 2023 Annual Meeting of Shareholders

P&G held our 2023 Annual Meeting of Shareholders.

Read more

10/11/2023

Four Ways We’re Working Together to Create More Opportunities for Girls to Lead

P&G and our brands recognize International Day of the Girl.

Read more

9/30/2023

Three Ways We Grow Our Disability Confident Culture

P&G recognizes National Disability Employment Awareness Month.

Read more

9/28/2023

Twenty Olympic and Paralympic Athletes Get an Early “Win” for Their Community Impact Partners

Ahead of the Olympic and Paralympic Games Paris 2024, P&G awards 20 athletes with a $24,000 USD grant for their charities to further their work.

Read more

9/27/2023

P&G Products Receive Good Housekeeping’s 2023 Best Cleaning & Organizing Award Recognition

10 P&G products are recognized as part of Good Housekeeping’s 2023 Best Cleaning & Organizing Awards Recognition

Read more

9/22/2023

P&G and Always Unite with Period Heroes to #EndPeriodPoverty

Global Citizen Festival Sets the Stage for Action

Read more

9/21/2023

2023 Annual Report – Integrated Strategy Series

Procter & Gamble shares additional insights into its integrated strategy, following the release of the company’s 2023 Annual Report.

Read more

9/16/2023

Innovation Expo Live Podcast Uncovers P&G's Science-Based Innovation

Procter & Gamble leaders share how we are resetting the bar for superiority and meeting consumer demands.

Read more

9/15/2023

Hispanic Heritage Month: Meet the Innovators Behind P&G’s Everyday Innovations

Throughout Hispanic Heritage Month, we’re introducing some of P&G’s Hispanic innovators behind the everyday products your family loves.

Read more

9/9/2023

P&G Myth-Busting Series: OLAY Scientist Shares Skin Care “Dos and Don’ts”

OLAY Launches New “Super” Product | P&G Myth-Busting Series

Read more

9/2/2023

P&G India Launches “Lead With Care” Program

Procter & Gamble launches a new caregiving support program for employees in India with children who have disabilities and special needs.

Read more

8/29/2023

Ending Animal Testing — Together

P&G scientists and animal welfare leaders step forward to end animal testing.

Read more

8/23/2023

OLAY is Putting the ‘Super’ in Super Serum

Innovation helped create OLAY’s newest Super Serum with super-powered ingredient — activated niacinamide.

Read more

8/19/2023

Closing America's Smile Gap: Partnering for Better Oral Health Access, Education and Representation for Kids in the U.S.

Crest and Oral-B Team up with Jesse Williams to discuss the importance of oral care supplies for Back-to-School 2023.

Read more

8/15/2023

Hip Hop Music Turns 50!

P&G Celebrates How Music Widens Our Views and Our World.

Read more

8/1/2023

How Much Do You Know About the Global Water Crisis?

To spread awareness about the global water crisis, P&G and Cascade partnered with The Guardian US to hit the streets and see how much people know.

Read more

7/15/2023

Women Deliver 2023 | Together We All Lead

Inspired by today’s generation of action & impact. Meet the women changemakers transforming their communities.

Read more

6/24/2023

Three Ways Our People Make Our Impact Possible

Our employees around the globe bring their unique perspectives and experiences to the brands you know and love.

Read more

6/24/2023

3 Leadership Tips From P&G’s Chief Operating Officer

Shailesh Jejurikar, P&G COO, offers new employees three ideas to consider as they create their own career path.

Read more

6/24/2023

Victor Aguilar, Chief Research, Development & Innovation Officer, Reflects on Inspiring Market Visits and the Drive for Irresistible Superiority

P&G employees around the globe are creating breakthroughs.

Read more

6/21/2023

P&G Myth-Busting Series: The Innovation Behind the New Swiffer PowerMop

The new Swiffer PowerMop is an all-in-one cleaning system that helps us all clean smarter, not harder!

Read more

6/13/2023

Innovation Series | How Head & Shoulders Delivers on Dandruff Protection and Sustainable Packaging

Innovation helped create Head & Shoulders’ new 9-ingredient, low-waste H&S BARE product line.

Read more

6/10/2023

A Force for Growth, Good and Hope | How P&G is Supporting the LGBTQ+ Community with Pride

P&G leads another year of Can’t Cancel Pride in support of the LGBTQ+ community and organizations that help create a more inclusive and equal world.

Read more

6/1/2023

P&G Shiksha Launches a Nationwide Movement in India to Make the #InvisibleGap Visible

In a first-of-its-kind thought-provoking film, P&G Shiksha aims to create awareness and urge meaningful action to bridge the invisible learning gap in India.

Read more

5/27/2023

Always, International Paper, and Period Heroes Team Up to Help #EndPeriodPoverty in the U.S.

Always heads to Washington D.C. to recommit to the brand’s mission to help #EndPeriodPoverty.

Read more

5/26/2023

Signal 2023 | P&G’s Annual Innovation Summit Draws Top Industry Minds to Cincinnati

P&G’s 12th Annual Signal Summit will Inspire Innovators to Rethink Success.

Read more

5/24/2023

P&G and Conservation International: Partners to Protect and Restore Biodiversity

Through a five-year partnership with Conservation International, we’re working to restore and protect one of the most biodiverse regions on Earth.

Read more

5/18/2023

Creating a More Digitally Accessible World

People with Disabilities Belong at P&G.

Read more

5/13/2023

When Love Comes Early: A Pampers’ NICU Nurse Becomes a NICU Mother

NICU nurse Amy Wiford shares a piece of her motherhood journey – going from working in the NICU to being the mother of a patient in the NICU.

Read more

4/26/2023

P&G Myth-Busting Series: Bounty on a Roll with New Innovation

P&G Scientist Gregg Weaver shares how cleaning up messes is easier than before with the Quicker Picker Upper.

Read more

4/25/2023

Global Inclusion: If the Systems Don’t Change, Change the Systems

Chief Communications Officer Damon Jones outlines how multicultural and inclusive marketing are fundamental to brand building.

Read more

4/18/2023

P&G Employees Give Back to Help Our Communities Grow

In celebration of National Volunteer Month, we share Acts of Good that our employees are doing, alongside our partners, to help their communities grow.

Read more

4/11/2023

In Memoriam — Edwin L. Artzt

Remembering our former CEO for his visionary leadership, competitive spirit and commitment to P&G people.

Read more

4/6/2023

Spring Cleaning with P&G Innovation

Our P&G experts share how our innovative products keep your home fresh all season long.

Read more

4/6/2023

A Long History of Misspelling Our Company’s Name

Search P&G online and you’ll find endless variations of the spelling of Procter & Gamble — but we haven't always gotten the name quite right ourselves!

Read more

4/5/2023

Meet the Innovators Behind P&G’s Sustainability Efforts

Meet the innovators that help create products and processes that help drive P&G’s sustainability goals.

Read more

4/1/2023

World Autism Awareness Day: Neurodiversity Confidence Grows at P&G

Celebrating the Contributions of Our Neurodivergent Talent.

Read more

3/24/2023

P&G and The University of Cincinnati Expand Collaboration and Celebrate 15-Year Partnership with Digital Accelerator

Partnership continues to bring students real experience while solving business challenges with newly-renamed P&G Digital Accelerator @ the University of Cincinnati.

Read more

3/23/2023

P&G Helps to Build a Water Positive Future

World Water Day is grounded in collaboration and unlocking new approaches to solve water challenges, and P&G continues to help advance everyday solutions.

Read more

3/16/2023

The Power of Innovation and Partnerships: Transforming Lives through Clean Water

For World Water Day 2023 P&G is highlighting the power of partnership in helping to accelerate efforts to solve the water and sanitation crisis.

Read more

3/7/2023

Four P&G Brands Raise the Bar with Accessible and Sustainable Packaging

Ariel, Gillette, Herbal Essences and Lenor Recognized for inclusive design that drives sustainability.

Read more

3/3/2023

Women’s History Month: Meet the P&G Innovators Behind the Innovation

Throughout Women’s History Month, we’re introducing some of Procter & Gamble’s innovators behind our everyday product innovations.

Read more

3/2/2023

Six Award-Winning Packaging Designs Inspire Sustainability At Home

Learn about the innovation behind these sustainable packaging designs.

Read more

3/1/2023

LGBTQ+ History Month: Learning from Personal Stories

P&G is a company that values diversity and strives to create a world free from bias – both inside our organisation and in wider society.

2/28/2023

Work Is Changing; Workspaces Are, Too

At P&G, we’re making sure our offices are engaging workspaces that support the way people work today and are ready for the future.

Read more

2/28/2023

Colleagues Share Inspiring ‘P&G + Me’ Stories

Hear in their own words why these team members say P&G is an unbeatable place to build a career.

Read more

2/11/2023

P&G Celebrates Black History Month 2023

We recognize and celebrate Black History Month by acknowledging the unparalleled impact the Black community has had on the United States throughout history.

Read more

2/11/2023

#InventorsDay: How Our Past Shapes Our Future

As we celebrate Inventors Day, Shane Meeker, our corporate storyteller and historian, sat down to talk with PR Week to share how understanding our past can help shape the future of our company.

Read more

2/7/2023

Procter & Gamble Innovates to Create Products That Are Accessible and More Sustainable

Through inclusive and sustainable design, we’re also helping consumers live more sustainably.

Read more

1/11/2023

P&G Myth-Busting Series: You’re Probably Cleaning Your Dishes Wrong. Our Dish Expert Explains

Procter & Gamble’s Dish Cleaning Myth-Busting Series.

Read more

12/23/2022

Innovators Series: Meet the Innovator Making Laundry Day Easier

There’s real science in your laundry regimen.

Read more

11/22/2022

Innovation Series: Behind P&G’s Bounty

There’s more to the Quicker Picker Upper than you think.

Read more

11/17/2022

Committed to Premature Babies, Their Families and Their Caretakers

This World Prematurity Day, Pampers and P&G continue to help raise awareness of preterm birth and the concerns of preterm babies and their families worldwide.

Read more

10/27/2022

2022 SAGE Awards: Celebrating the Inspirational Leadership That Is Transforming Our World

P&G celebrates Brent Miller for receiving the Jack Watters Corporate Advocate Award at the 2022 SAGE Awards & Gala.

Read more

10/22/2022

P&G Celebrates 40 Years of Partnership with Feeding America®

Together we’re advancing change and ensuring access to nutritious food and essential products.

Read more

10/21/2022

A Road Less Traveled

P&G Global Ambassador, Employees with Disabilities and Medical Conditions, Raymond Lynch’s Journey Advances the Disability Community

Read more

10/15/2022

LGBTQ+ History Is Our History

P&G honors the legacy of leaders in this community who’ve inspired changes within our company and engendered a greater sense of beauty and equity throughout the world.

Read more

10/14/2022

New OLAY Regenerist Hyaluronic + Peptide24 Collection Delivers Consistently Radiant Skin in Increasingly Inconsistent Environments

OLAY launches new Hyaluronic + Peptide24 collection, the most hydrating launch yet.

Read more

9/22/2022

Procter & Gamble: Protecting Forests for Generations to Come

Working with leading environmental and forestry groups, P&G continues to make progress on our commitment to keep forests as forests for generations to come.

Read more

9/16/2022

Our Pride, Our Legacy

P&G Celebrates Our 30-Year Commitment to LGBTQ+ Visibility, Equality & Inclusion

Read more

9/9/2022

P&G Myth-Busting Series: You’re Probably Doing Your Laundry Wrong. P&G’s Laundry Experts Explain

Procter & Gamble’s Fabric 101 Myth-Busting Series

Read more

9/3/2022

Children’s Safe Drinking Water Program Reaches 20 Billion Liter Milestone

In collaboration with our partners, we announced that we delivered 20 billion liters of clean drinking water to families around the globe.

Read more

8/31/2022

School of P&G: Where Learning & Development Take Center Stage

P&G’s unwavering commitment to leadership development puts learning, growth and ownership front and center.

Read more

8/31/2022

Innovation Series: Meet the P&G Scientist Helping Rid Your Home of Bugs

P&G Scientist Chris Smith Helps Develop a Safe, Set-And-Forget Product to Help with Household Bugs

Read more

8/20/2022

Innovation Series: P&G Trailblazer Helps Bring Water Positive Future to Life

Shannon Quinn spearheaded 2030 strategy enabling P&G to help address the global water crisis.

Read more

8/13/2022

Innovation Series: Meet the Engineer Behind the Oral B Connect App

P&G engineer discusses the advantages of working on a diverse team.

Read more

8/5/2022

Tide’s #TurnToCold Highlights the Benefits of Cold Water Washing

Tide’s latest fabric care innovations delivers superiority for both your clothes and wallet.

Read more

7/22/2022

P&G’s Signal Summit Helps Solve Problems of Tomorrow

More than 3,000 people attended the eleventh annual #PGSignal Summit for a day of innovation & inspiration.

Read more

7/12/2022

Tide Stain Remover Products to Launch into Space July 14

Tide To Go products take off this summer to further development of low-resource cleaning solutions.

Read more

6/10/2022

A Closer Look at P&G’s New Strategy to Help Address Global Water Crisis

A closer look at P&Gs recently announced strategy to help build a water positive future that includes new 2030 water goals.

Read more

6/10/2022

P&G Unveils New Strategy to Help Address Global Water Crisis

A comprehensive strategy that includes a first-of-its-kind goal to restore more water than is consumed during use of P&G products in two high water-stressed areas.

Read more

6/1/2022

Signal 2022 Underscores That ‘Innovation’ Isn’t Just a Buzzword at P&G

Dive in with us during this year’s Signal conference as we explore innovations of tomorrow and beyond.

Read more

5/25/2022

Be Seen, Be Heard — Can’t Cancel Pride

Meet the People and Organizations Driving Visibility and Making Impact Toward Equality & Inclusion During Pride Month

Read more

5/19/2022

Meet Thibault Trancart: A True Accessibility Champion at P&G

Cancer led to his loss of sight. “It was the most beautiful thing that happened to me.”

Read more

4/30/2022

9 Elements Adds Foaming Dish Spray to its Vinegar-Powered Cleaning Line-Up

Easy to use vinegar-powered dish spray from P&G brand also comes in refill model.

Read more

4/22/2022

Next Stop: Tide Infinity Heads to the Hill

Tide representatives met with leaders to discuss innovations that will drive forward the cleaning solutions of tomorrow for Earth and space.

Read more

4/13/2022

In Memoriam - Durk I. Jager

Remembering our former CEO for his entrepreneurial spirit and courageous leadership during a time of unrelenting change.

Read more

4/6/2022

Responsible Beauty: How P&G is Using Guar

P&G Beauty announced it will double the global supply of sustainably farmed guar in India.

Read more

4/2/2022

P&G Recruits and Supports Neurodivergent People

From Costa Rica to Ireland, from the United Kingdom to Singapore, learn how we are creating a disability-confident culture.

Read more

3/26/2022

Sleep Tips & Sleep Myths: Join ZzzQuil’s Guide to Better Sleep in 1-2-Zzz

For National Sleep Awareness Month, ZzzQuil busts sleep myths and shares tips for better sleep.

Read more

3/8/2022

Update on P&G's European Operations

Letter to P&G employees on European Operations, from Jon Moeller, P&G’s President and CEO.

Read more

3/2/2022

Leveraging Technology to Improve The Lives of P&G Consumers

Data and technology allow us to continue to improve P&G products and experiences.

Read more

2/18/2022

Meet the P&G Innovator Who Disrupted the 60-Year-Old Coupon Industry

Meet the P&G Innovator who created a solution to the long-time issue of coupon fraud.

Read more

2/9/2022

P&G’s Film Coded Brings Legendary Illustrator’s Story to Life

Award-winning film is the latest in P&G’s efforts to authentically portray LGBTQ+ people in its media and advertising.

Read more

12/21/2021

Tide is Headed to Space!

Tide will take its first step towards a viable laundry detergent solution for space-faring astronauts for many decades to come.

Read more

12/21/2021

P&G Science Lifts Off With NASA

Check out how P&G and our brands are using space-age discoveries to benefit our consumers here on Planet Earth.

Read more

10/13/2021

Our Progress on Sustainable Forestry

P&G shares an update on our efforts this year to protect our forests, helping to ensure no one has to choose between the products they use today and what they hope to preserve for tomorrow.

Read more

9/23/2021

P&G + Me: Giving our Best to One Another Every Day

We’re inspiring our employees to bring their full selves to work and to help one another through our new EVP “P&G + Me = Mutual Success.”

Read more

9/15/2021

A Closer Look at P&G’s Net Zero 2040 Ambition

We announced our ambition to achieve net zero greenhouse gas (GHG) emissions across our supply chain and operations by 2040, from raw material to retailer. But what exactly does it all mean? Let’s break it down.

Read more

9/15/2021

P&G Accelerates Action on Climate Change Toward Net Zero GHG Emissions by 2040

Today, we announced a comprehensive plan to accelerate action related to climate change.

Read more

9/15/2021

From A-choo to A-ha! Unlikely Innovations

There’s a whole lot that goes on behind-the-scenes with Vicks product development, especially when it comes to our ingredients.

Read more

8/25/2021

Using Science For Good— An End To Animal Testing Globally

Our goal—a world without animal testing—is getting closer thanks to the commitment of our scientists and brands.

Read more

6/30/2021

Be Seen, Be Heard: Driving Visibility of the LGBTQ+ Community

Growing up, Brent Miller never saw himself represented in the media he consumed. As P&G’s first-ever Global LGBTQ+ Equality Program Leader, Brent makes it a priority to accurately portray all people in everything we do.

Read more

6/19/2021

Meet The “Mother of Forests” Advocating for Responsible Forestry Practices

Stacey Locke still remembers the first time her grandmother brought her to their family’s forest. Fifty years later, she is one of the land stewards who supply wood pulp used to make our Charmin toilet paper.

Read more

6/16/2021

Can washing your clothes on cold with Tide and Ariel do a world of good?

The most significant environmental impact your laundry has is the energy used to heat the water in your washing machine. That’s why Tide and Ariel are leading the way to a more sustainable future by encouraging people to switch to cold-water washing.

Read more

6/12/2021

Downy Infusion Scents Ranked #1 on IRI’s 2020 New Product Pacesetters List in the Nonfood Category

Several of our brands and products were recently recognized on IRI’s 2020 New Product Pacesetters and Rising Stars lists that celebrate the year’s most successful product launches in the U.S. – with more of our products landing on the list than our top sev

Read more

3/22/2021

P&G Family Care Accelerates Forest Conservation Efforts

Forestry actions and accelerated commitments from Charmin, Puffs, and Bounty help bring to life P&G's Ambition 2030 goal of protecting and enhancing forests — raising the bar on conservation, transparency and accountability.

Read more

2/26/2021

P&G supports Equality Act

P&G has publicly supported The Equality Act since 2016. With a passage in the House, we would be one step closer to guarantee non-discrimination protections for LGBTQ+ people and to strengthen our civil rights laws for all Americans.

Read more

10/15/2020

P&G and Responsible Forestry

Our shareholders have asked us to issue a report assessing how we can increase the scale, pace, and rigor of our efforts to eliminate deforestation and the degradation of intact forests. We look forward to sharing this information on www.pg.com.

7/23/2020

P&G Announces Extended Olympic Games partnership

Today we announced the extension of our Olympic Games partnership with the International Olympic Committee (IOC) through Los Angeles 2028, including new global rights with the International Paralympic Committee (IPC) and the Paralympic Games.

6/19/2020

Perspective on U.S. Supreme Court Ruling on Employment Equality

On June 15, 2020, the U.S. Supreme Court ruled that an employer who fires an individual merely for being gay or transgender violates Title VII of the Civil Rights Act of 1964. In 1992, P&G become one of the first

5/28/2020

P&G and GLAAD’s New Study Reveals the Power of LGBTQ+ Inclusion in Advertising

At P&G, we have the opportunity to use our voice to address bias and create productive conversations. This commitment to using our reach as a force for good and a force for growth rings especially true as we prepare to celebrate Pride Month during

3/20/2020

STEPPING UP AS A FORCE FOR GOOD

In service to people everywhere who are caring for their families and communities — all day, every day, P&G people are stepping up and serving others as a force for good.

10/5/2019

P&G’s FAMILY CARE BRANDS SHARE NEW SUSTAINABILITY GOALS FOCUSED ON FORESTRY

Just this week, P&G’s Family Care brands set new industry-leading commitments for their paper products to protect, grow, and restore forests globally. These new commitments span all P&G Family Care brands, including Charmin,

9/18/2019

P&G to Invest in FGV’s Remediation Efforts in Support of Human Rights

At P&G, respecting human rights is fundamental to how we manage our business. We support the UN Guiding Principles on Business and Human Rights and expect our business partners to operate in the same manner.